Asset Management

PPS ensure operational excellence by maintaining an impeccably managed fleet through our Computerised Mainte...nance Management System (CMMS). Our equipment, tracked via GPS for optimal performance and safety, is always “go line ready” for immediate productivity. Our state-of-the-art IVMS technology monitors vehicle and driver conditions in real-time, while our off-site maintenance facilities, staffed with expert technicians, provide superior technical support, keeping our machinery in top condition for deployment.

Major Projects

Trusted turnkey water management solutions. Assisting in the management and/or execution of greenfield major... mining projects or major water infrastructure expansions. Our services cover a wide range, including but not limited to the building of Water Treatment Plants, Pump Stations, Reverse Osmosis (RO) Plants, and Storage Tanks and related in-ground and above ground water pipe line infrastructure.

Manufacturing

Plummers Industries has been in operation since the 1950s and has a long-standing reputation for excellence... in the manufacturing industry, particularly in the design and construction of switch rooms, sheet metal, MCC’s, switchgear, and control panels. The Plummers Industries business is currently operational in Western Australia, Queensland and Victoria.

Year to date

317,370.38

Meters of Pipe Laid

15,868.62

Welds Completed

4,108.47

Daily Meterage Laid

204.12

Daily Welds Completed

We've got it all covered.

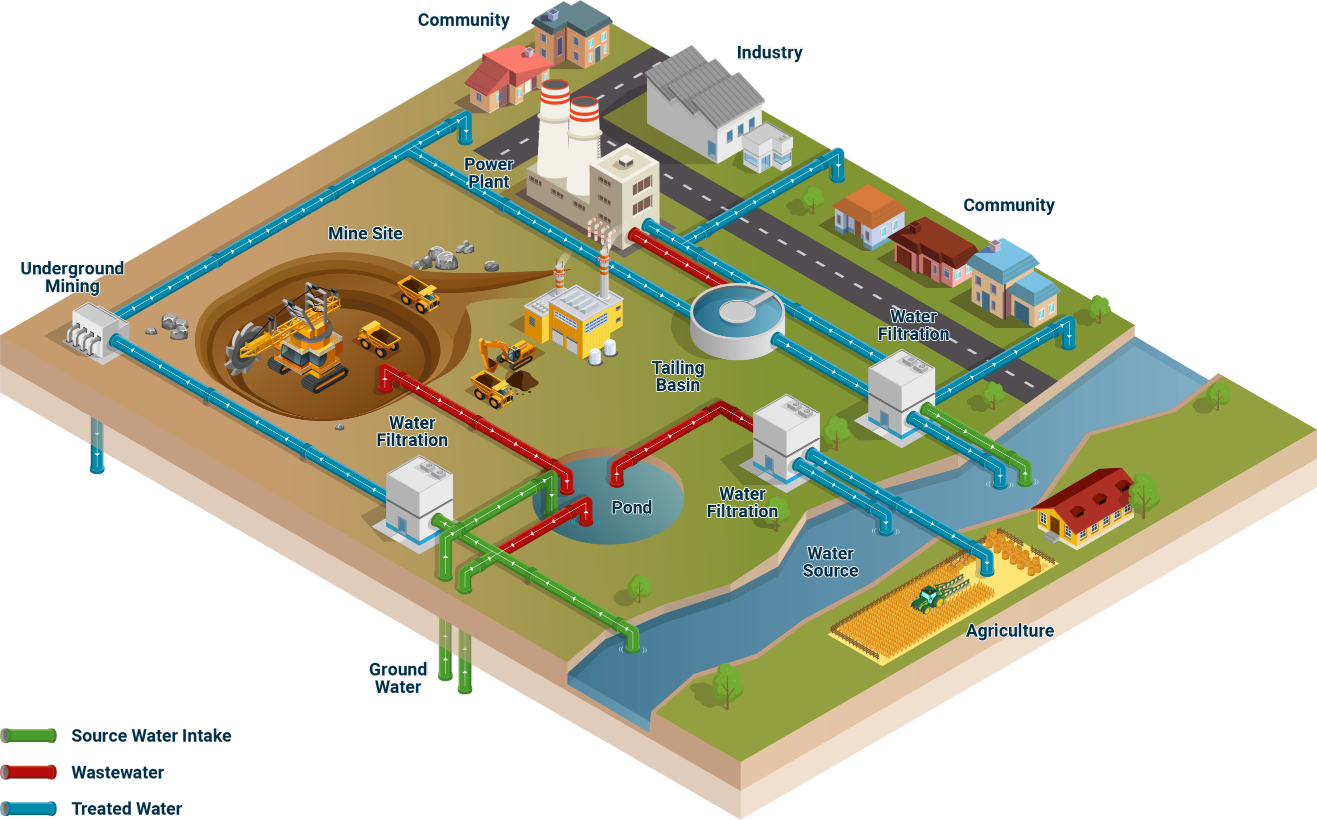

Water Stewardship is the key to any industrial or mining project. PPS Water Group has the necessary expertise to engineer, install and commission your project to meet the demands of today and future proof for tomorrow.

Who we work with.

Looking after our world for over 25 years.

We have partnered with the majority of major mining and industrial projects across the state and have set the standard for efficiency and innovation.

Our future.

Water stewardship is critical for the success and longevity of industrial projects, especially as we undergo the energy transition. With the ongoing effects of climate change, the issue of fresh water supply is increasingly pressing. According to the International Resource Panel (IRP), almost half of the world’s population is expected to face water stress by 2030.

During this same timeframe, energy, chemicals, and resources suppliers will require billions more litres of fresh water to operate the water-dependent projects necessary for achieving decarbonisation goals. It’s crucial for every water-intensive industrial business to reconsider their relationship with water, which is our planet’s most valuable resource.

As we confront these water challenges, PPS is committed to working closely with our customers to promote water stewardship throughout their operations. Our objective is to provide sustainable and responsible solutions for accessing, treating, using, and disposing of water. We help our customers by assessing potential water resources, optimising water treatment systems, desalination plants, and wastewater facilities.

At the core of sustainable water management is a comprehensive approach to water projects, taking into account everything from groundwater modelling in the early stages of a project to the responsible decommissioning of water infrastructure. Our process begins with providing advisory and regulatory services that promote responsible water usage in projects. This informs our design management and construction of water facilities. We also assist our customers with storing and distributing water, maintaining their water assets, and conducting water monitoring in the field.

Our success stories.

We facilitate our clients’ projects as if they were our own.

We set our reputation apart, beyond services, labour hours or price competition, we are an enriching source of reliable expertise, leading with innovation, efficiency, and sustainable outcomes for a greener planet.